High-pressure refrigeration systems operate under stressing conditions, often requiring components that will withstand high working pressure and provide efficient heat transfer. They seem to dominate industrial cooling, commercial refrigeration, and high-end HVAC applications where performance and reliability are non-negotiable. In this context, microchannel heat exchangers have proven themselves a durable alternative to traditional coil designs—offering greater pressure capacity, improved thermal efficiency, and lower maintenance needs.

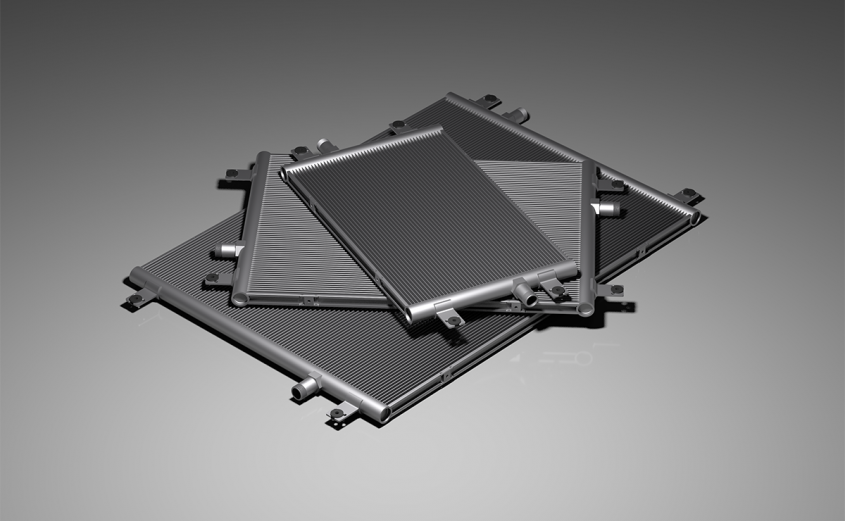

At the heart of this capability is microchannel coil structural design. Unlike conventional round-tube coils, which are founded upon many brazed joints and mechanical interfaces, microchannel heat exchangers utilize flat aluminum tubing with multiple internal flow channels. This configuration not only maximizes surface area for better heat exchange but also allows for more even pressure distribution across the coil structure. Therefore, these coils can handle the higher operating pressures of modern refrigerants like R-410A, R-32, and even CO₂-based (transcritical) applications.

Being a key benefit of using carrier microchannel coil technology in high-pressure applications is that it ensures consistency of performance without compromising on robustness. Copper-aluminum coils, as traditionally used, can suffer from stress fractures or leaks due to uneven pressure distribution as well as corrosion susceptibility. Microchannel coils, built primarily of aluminum and with fewer joints and seams, significantly reduce the possibility of failure by pressure cycling and vibration—common problems with rooftop units, chillers, and transportation refrigeration.

Beyond that, internal microchannel tube structure promotes enhanced refrigerant flow characteristics. The multi-channel design facilitates uniform refrigerant distribution, eliminating hotspots and ensuring stable operation even when load conditions vary. This means more efficient system performance, lower compressor discharge temperatures, and less energy consumption—issues that have direct implications for cost of operation as well as equipment longevity.

Optimized Design for Challenging Applications

Pressure drop and refrigerant charge must be controlled in high-pressure refrigerant systems. Microchannel heat exchangers are better at this than coils by requiring less refrigerant charge. This is particularly useful in the use of newer, low-GWP refrigerants that are slightly flammable or have very limiting regulatory requirements. By reducing the quantity of refrigerant needed to deliver an equivalent amount of performance, microchannel coils support environmental compliance, improve system safety and efficiency, and assist in guaranteeing lower emissions.

Moreover, microchannel coils are small in size and light in weight, making them ideal for integration into pressure-high systems where weight and space are considerations. Whether used on condenser sections of high-efficiency chillers or evaporator units in cold storage use, microchannel technology enables engineers to design more efficient, service-friendly systems without sacrificing capacity or reliability.

For the technicians and facility managers of Carrier-based systems, the transition to carrier microchannel coil replacements offers a practical means of advancing system reliability. The majority of the older Carrier units were originally constructed with heavier, less efficient coil designs that are more prone to corrosion or failure under pressure. Replacement with new microchannel versions involves the immediate advantages of enhanced thermal efficiency, lifespan, and long-term cost savings—all without major reconfigurations of the original system design.

Conclusion: A Reliable Choice for High-Performance Refrigeration

As refrigeration systems further evolve towards higher efficiency, smaller environmental impact, and more stringent performance specifications, the role of advanced thermal components like microchannel heat exchangers cannot be emphasized enough. Their dependability under performance at high-pressure operation, coupled with better thermal transfer and reduced refrigerant consumption, makes them a smart choice for existing refrigeration engineering.

Whether in a new system or upgrade to an installed base, microchannel technology use offers real-world benefits—increased system efficiency, longer life, and less required maintenance. To those seeking durable, high-performance solutions that can match high-pressure refrigeration demands, the transition to microchannel heat exchangers is a step beyond technology upgrade—it is a bet on intelligent, sustainable thermal management